Expanding your distribution network but unsure where to begin? Many organizations recognize the need for capacity but are uncertain whether to invest in bulk storage, e-commerce distribution, automated fulfillment, a replica of existing sites, or a combination thereof. We collaborate with you to understand your business model and recommend solutions that best fit your short- and long-term needs.

Warehouse Process Design

SCT works to analyze your current facilities and network capacity while assessing your future needs. Building a new site offers a strategic opportunity to align your distribution flow with evolving business goals—avoiding yesterday’s solutions for tomorrow’s challenges. Through comprehensive studies of product flow, mix, demand patterns, and capacity, we help define not only what the facility should look like but also your labor requirements, appropriate automation levels, budgets, timelines, and stakeholder communications—both internal and external.

Facility Design & Engineering

Designing an agile, cost-effective distribution facility requires deep knowledge of software, hardware, and automation vendors—especially in a market crowded with “turnkey” providers that may not fully meet your unique business needs.

At SCT Advisory, our approach begins with evaluating your distribution strategy, followed by detailed assessments of order profiles, business processes, and throughput requirements. We develop scalable, flexible facility designs that leverage the latest automation technologies. From design through implementation and ramp-up, SCT provides end-to-end oversight to ensure your facility operates at peak performance.

Our Approach

We facilitate workshops with sales and operations leadership to challenge assumptions about distribution channels and needs, delivering a shared vision for immediate requirements and longer-term roadmap possibilities.

Using order profiles and slotting logic, we conceptualize automation usage and order selection strategies. We evaluate pallet, case, and unit picking processes alongside item velocities to recommend optimal storage and automation solutions. High-level budgeting includes systems, peripherals, security, vehicles, equipment, and professional services.

Whether your operation involves high-volume centralized DCs favoring turnkey solutions or broader networks requiring agile vendor relationships, SCT designs flexible system architectures and defines WMS/WES/WCS integration requirements.

Partnering closely with Procurement, SCT identifies critical success factors for vendor selection, documents requirements, evaluates proposals, and helps select providers capable of delivering best-in-class solutions tailored to your facility.

After real estate selection, SCT provides program planning and oversight—ensuring timely delivery and installation of equipment and systems, quality standards are met, associates are trained, and inventory levels support a smooth ramp-up to meet customer demand.

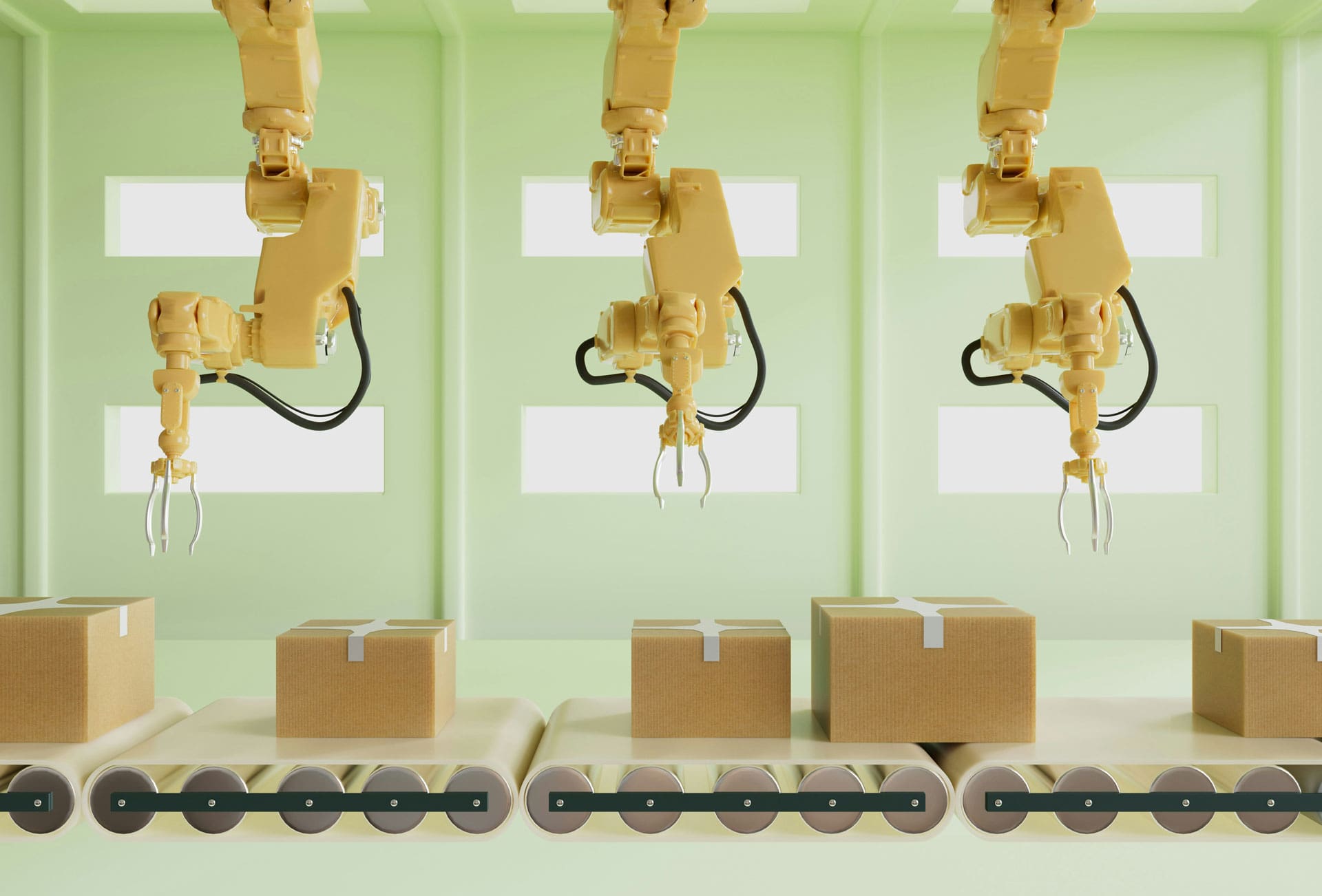

Automation Design & Engineering

As distribution shifts toward e-commerce, increased volume and velocity demand greater automation to keep pace. The SCT team has extensive experience in selecting, defining requirements for, implementing, and testing automation solutions—from conveyors and robotics to automated storage and retrieval systems. Our expertise in managing capacity, optimizing flow, and documenting technical specifications ensures your automation projects succeed and keep your supply chain running smoothly.